Empowering Your Operators

Universal, Device-Agnostic Scanning

Leverage the power of universal QR code scanning – no specialized hardware required. TundraSF works seamlessly through any device with a camera and a browser, whether it's a PC, smartphone, or tablet. This flexibility means rapid deployment, reduced IT overhead, and an accessible tool for every operator, eliminating the need for fixed workstations.

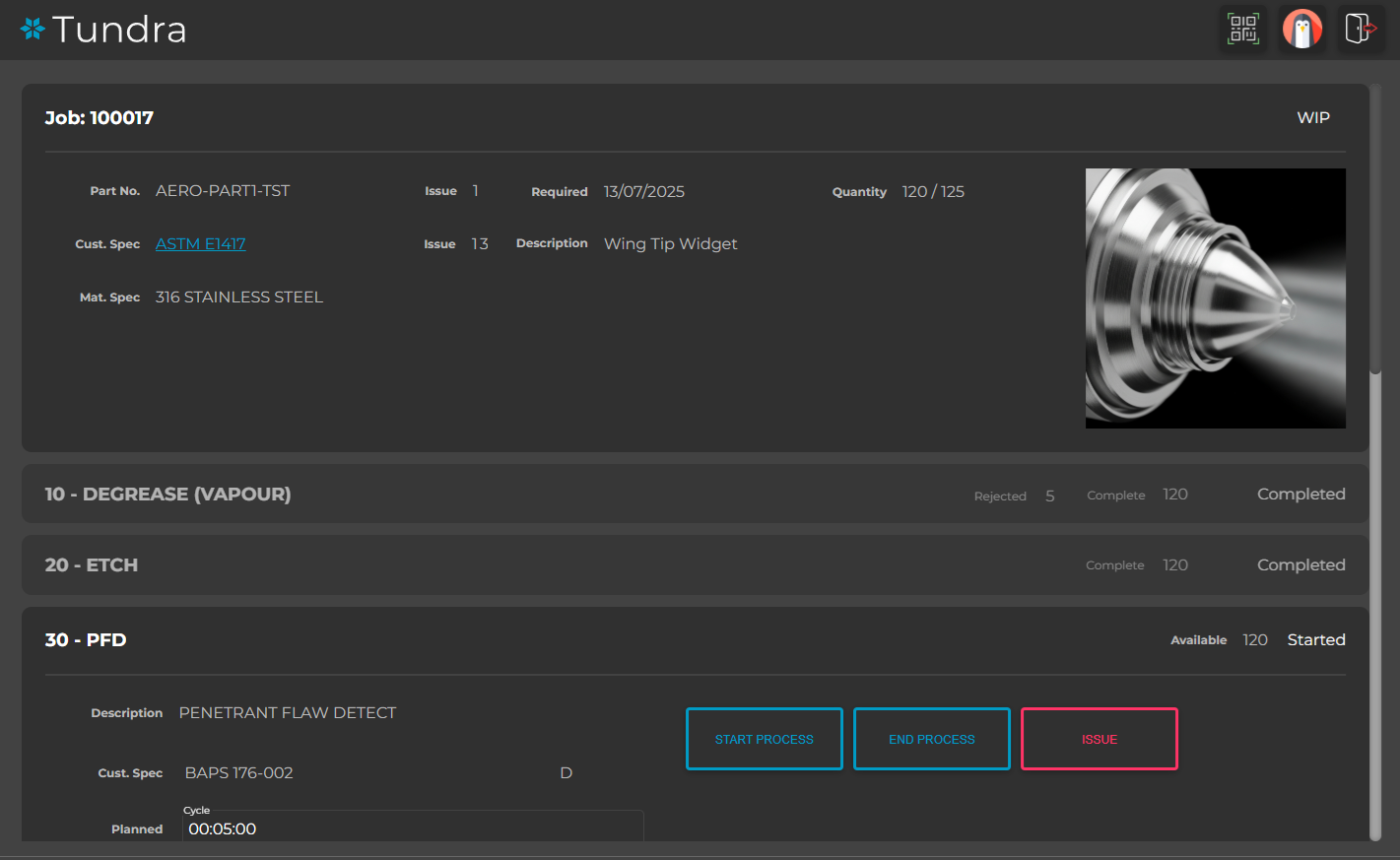

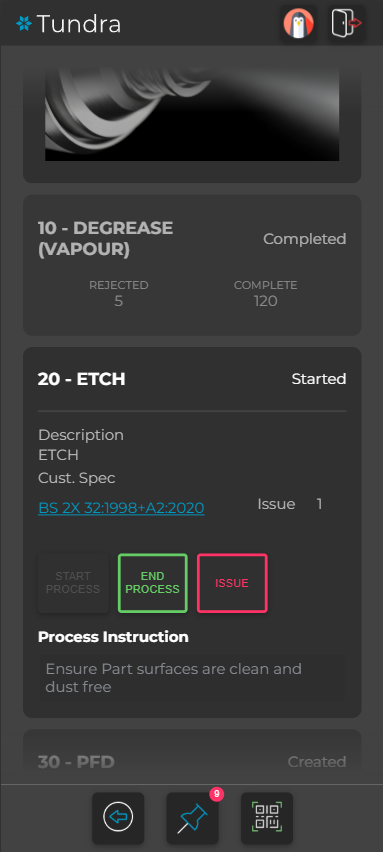

Real-Time Quality & Issue Management

Gone are the days of manual entry and delays. Operators can instantly log precise clocking’s for job start and finish, accurately track setup, cycle, and process times, and efficiently manage stock movements (in/out) with a simple scan. This real-time data capture ensures unparalleled accuracy and provides immediate insights into your production flow. Links to the user qualification framework ensures operators only progress tasks for which they have the appropriate training or qualifications.

Streamlined Task Management

With data flowing directly from the shop floor, task management becomes effortless. Operators have the tools to efficiently progress jobs, record events, and update statuses, leading to a smoother, more transparent production environment.