Production Mastery for Quality & Throughput

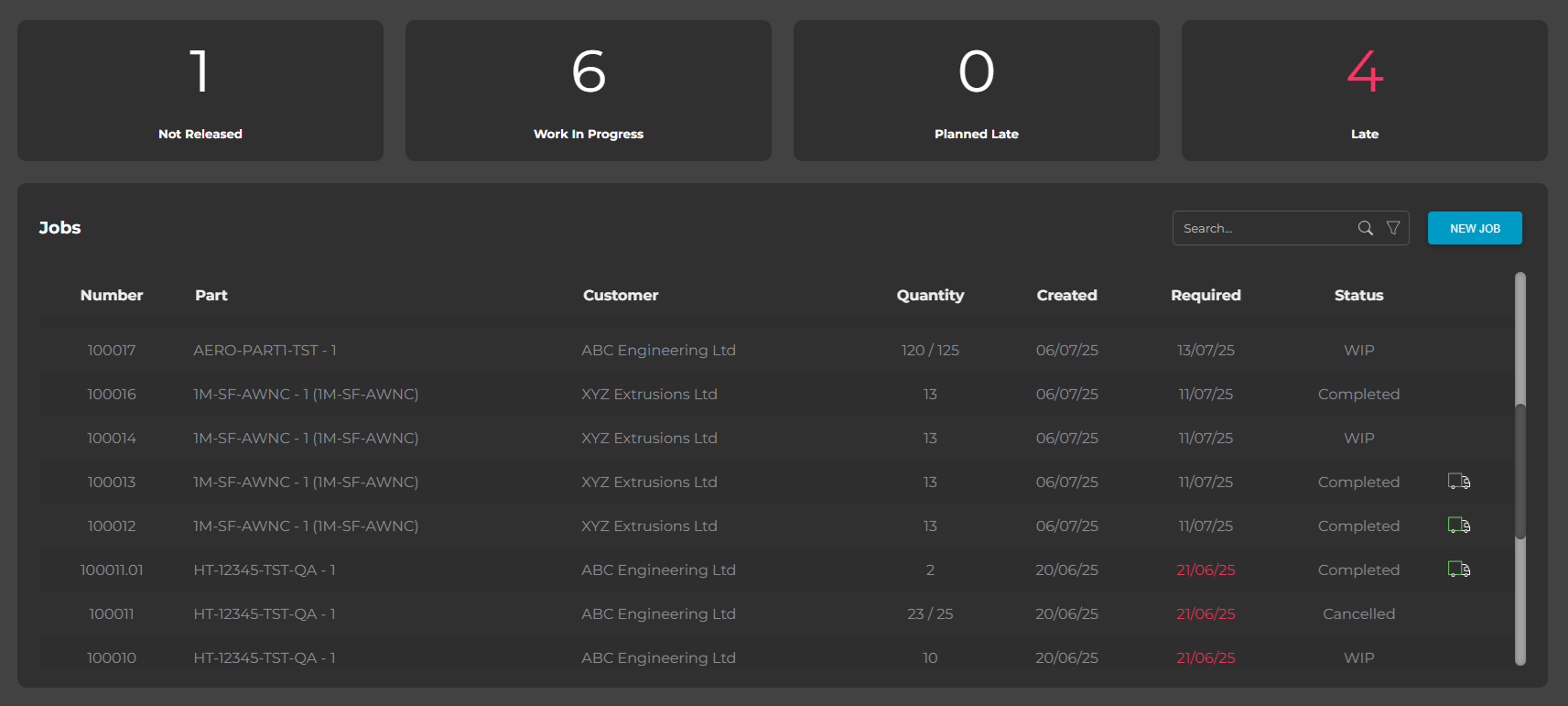

Live Production Monitoring & Defect Containment

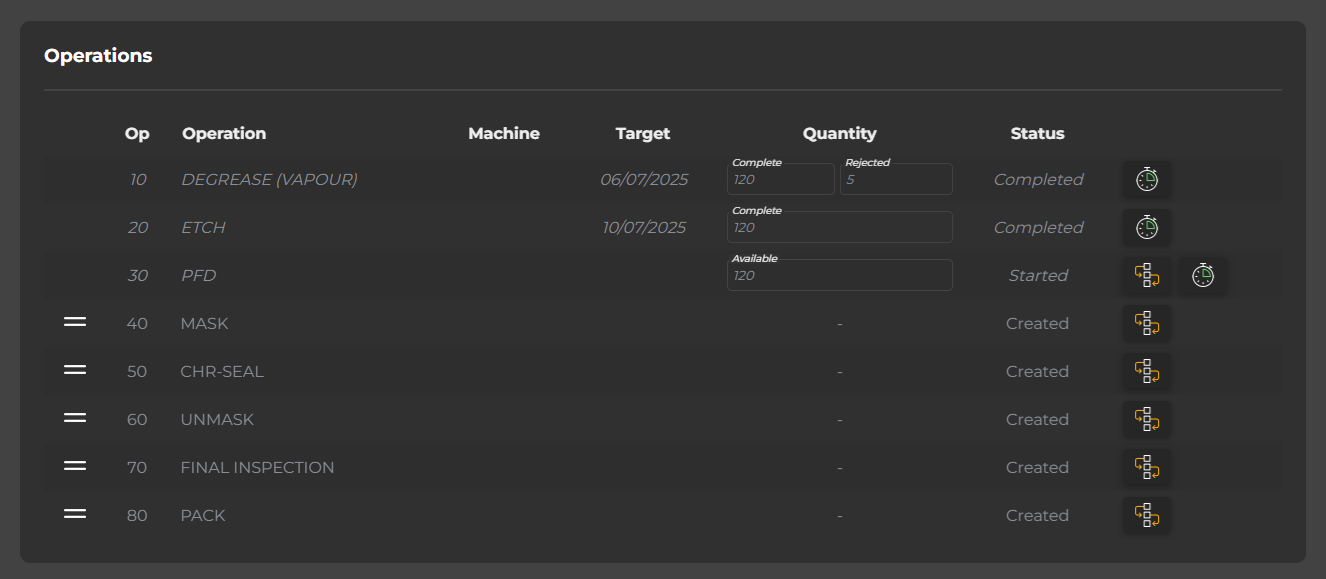

Enhanced tracking of progress and identification of bottlenecks.

Real-time production visibility to rapidly identify and resolve issues.

Complete production traceability, including tracking at the serial number level. This is crucial for the precise monitoring of each item during the production process. Ensuring compliance to regulatory standards.

Capture non-conformance as they happen during production and testing.

Track and Control the Process

Whether you use traditional Job Packs with parts or prefer a mostly paperless system moving only labels, we’ve got you covered.

Track real-time process progress with TundraSF.

Or simply monitor completed jobs with a single click.

Split, Optimize, Perfect: Smarter Production Flow

Flexible job splitting functionality, crucial for maximising shop-floor throughput. Improving task allocation and resource management.

Data-driven decision-making to optimise production efficiency.

Quality notifications to production for part specific instruction, images and video to ensure better product quality, reducing non-conformance and improving customer satisfaction.

Book a free consultation ~

Book a free consultation ~